IWST Industrial Meet: Plywood Panel & Furniture Meet

- August 7, 2024

- 0

QCO was discussed in the Industrial Meet at IWST. The programme was organised in honour of outgoing IWST Director Dr. MP Singh.

The speakers praised the tenure of Dr. MP Singh and explained how he has taken the wood industry to new heights by bringing agroforestry, technology, quality and industry on one platform.

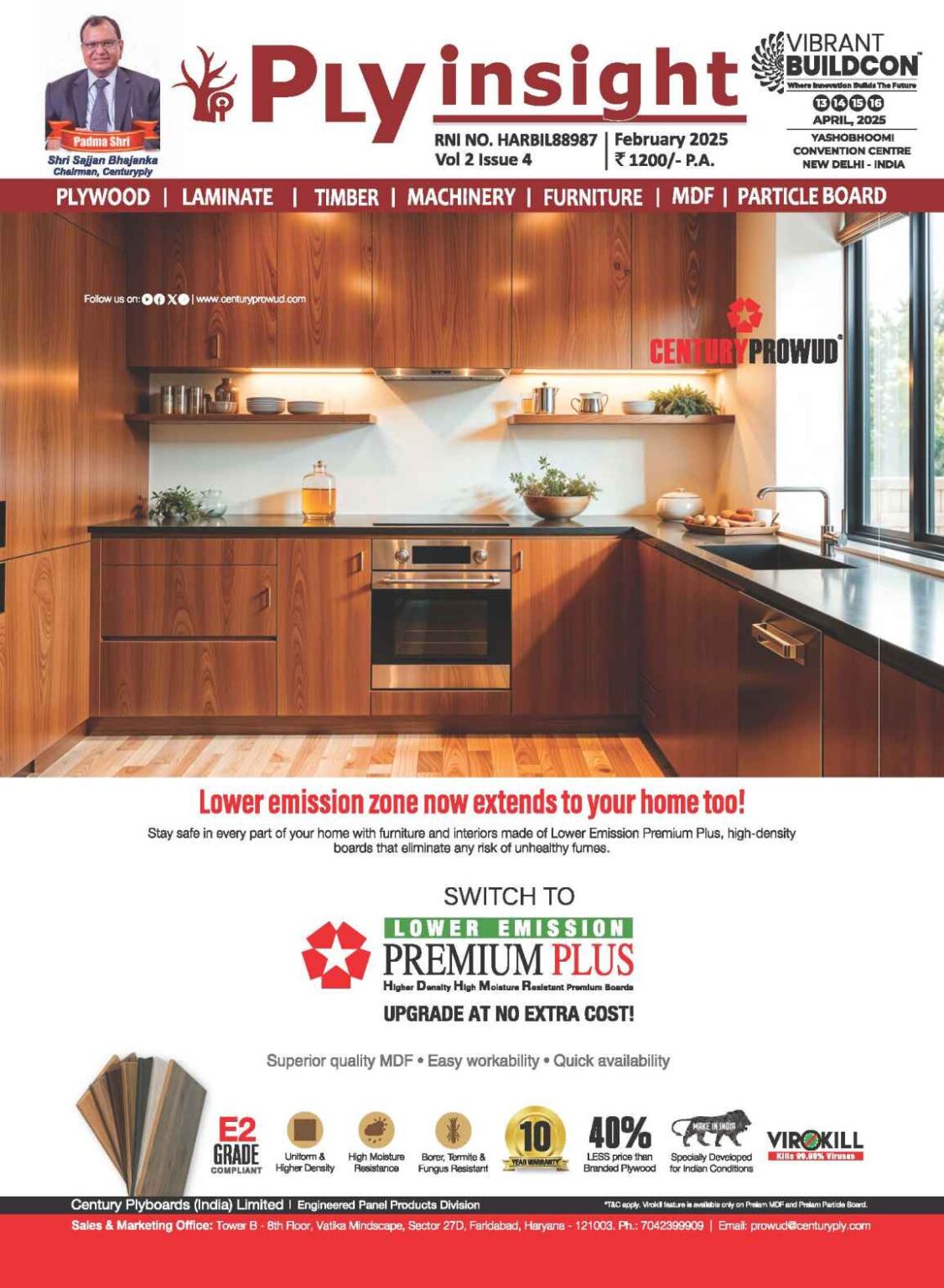

There are challenges, but there will be a way out from here only: Sajjan Bhajanka, Chairman, Century Plyboard

At present, we are facing the problem of ra w material. The prices of wood have more than doubled in the last 2-3 years. The industry has also increased its production capacity. Now, there is neither demand in the market, nor is sufficient raw material available.

In such a harsh situation, exploring the market for our finished product is a challenge. Even in all these circumstances, I am positive on the future. I believe that in the coming days, demand will surge, both in panels and furniture.

Demand for furniture is increasing in India. Furniture market has been growing continuously in the past ten years. Panel industry is also growing in the same proportion.

Our industry is parallel to international standards: Dr. MP Singh

Plywood of every category is available here. We have the best technology in the world. Our technology is capable of making wood products in accordance with the standards of BIS. As far as raw material is concerned, many industrialists have started working a lot in this direction. The government is also planning in this direction. So that more and more trees can be planted in collaboration with industrialists. Like the paper industry, such a successful effort is possible in the ply industry as well.

We are passing through a phase of change: Jaideep Chitlangia MD Duroply Industries Limited

We are passing through a phase of change right now. I am confident that the industry will adopt these challenges and move forward on the path of development. Dr. MP Singh has done a lot of work on QCO. He has implemented the changes proposed by the industry. The industry has started working on agro forestry. BIS should run a vigorous awareness campaign.

There are 3000 to 3500 producers in the country right now. Only 800 industrialists have licenses. It is a big challenge to create awareness so that all industrialists come under the purview of licenses.

Furniture and panel industries are interdependent: Rajesh Mittal, Chairman Greenply Industries Ltd

Furniture and panel industries are dependent on each other. As far as plantation of trees as raw material is concerned, it is definitely a big issue. We are running a plantation campaign unabated for the last two-three years in collaboration with farmers. Because our industry is completely dependent on agro-forestry.

Our biggest problem is low quality imported panel products. Another one is low quality imported furniture. QCO is able to stop low quality wood products being imported into India. This will strengthen the country’s economy.

Quality control standards are a big step towards making the country self-reliant: Mohammad Israr Ali, Director DPIIT

Quality control standards are a big step towards a self-reliant country. This can stop low quality wood products from coming to India. QCO will become mandatory from February next year. This will provide security to the Indian wood industry, the quality will improve as well. Because when the quality improves, our product can be marketed everywhere in the world.

Some ideas have come up regarding BIS for changes. They are being implemented after discussion. Some doubts were also raised in the last month’s meeting, this was mainly about fees and samples. We are confident that BIS will pay attention to all these things and take steps towards their smooth resolution.

QCO is being implemented finally. Therefore, now the industry should come forward and get the BIS license.

We are creating awareness about QCO: Narendra Reddy, Director Bureau of Indian Standards

BIS is now mandatory. It is a technical standard of quality. This will give a boost to the industry. This will not only make our product assessable in the local market but also in the international market.

To help MSME, they have been provided an additional six months. This is very important. MSME can prepare itself according to the standards with this extra line. Work is going on to create awareness through the manak manthan program. Short courses are also being organized regarding standards. Industrialists should develop their own laboratories. After the implementation of QCO standards, goods will have to be imported as per these standards.

Along with international quality, we also need reasonable prices: Aman Barota, Furniture Manufacturer

I export, Can goods of international quality be made in India, and can we get them at the same rate? Will we be able to get goods at the prices of the imported goods for our furniture? If you are able to supply us the goods as per these standards, we will buy the goods from you. Even If Indian goods are 8-10% costly than the imported ones, then it is fine. But if the difference in the rates is more than this, then the customer will face problems. He is not in a position to pay more for the local goods than the imported goods.

Laminated ply will also be under the purview of QCO. There is a challenge in it, it gets bent. DPIIT is requested to call a meeting of Indian producers, importers and exporters to discuss this.

There are many doubts about BIS. But we can say that it is in our interest. We want exports from India, not imports.

Rajesh Mittal MDF manufacturer: Today India is in a position to provide the best quality product at a reasonable price. We have good machines, better technology.

SN Chamaria, C.E.O. Eximcorp India Pvt Ltd

Why is there no third party certification? BIS has made standards, that is enough, now there should be a different agency to give certification.

Skilled people are needed for good quality: Jikesh Thakkar, Ex. Director, AIPM & ILMA

Today we need trained and skilled people for the industry. The production of MDF and particle board is increasing continuously. MDF has reached 15 thousand cubic meters per

day and particle board 17 thousand cubic meters per day in 2024. We expect demand for 60 thousand cubic meter for MDF and 35 thousand cubic meters of Particle board per day by 2031. Raw material will be required for this. How will it be full filled, is the big question. We are in touch with farmers so that raw material can be easily amvailable to the industry.

👇 Please Note 👇

Thank you for reading our article!

If you don’t received industries updates, News & our daily articles

please Whatsapp your Wapp No. or V Card on 8278298592, your number will be added in our broadcasting list.