What is Plywood Flooring?

Types of Plywood flooring

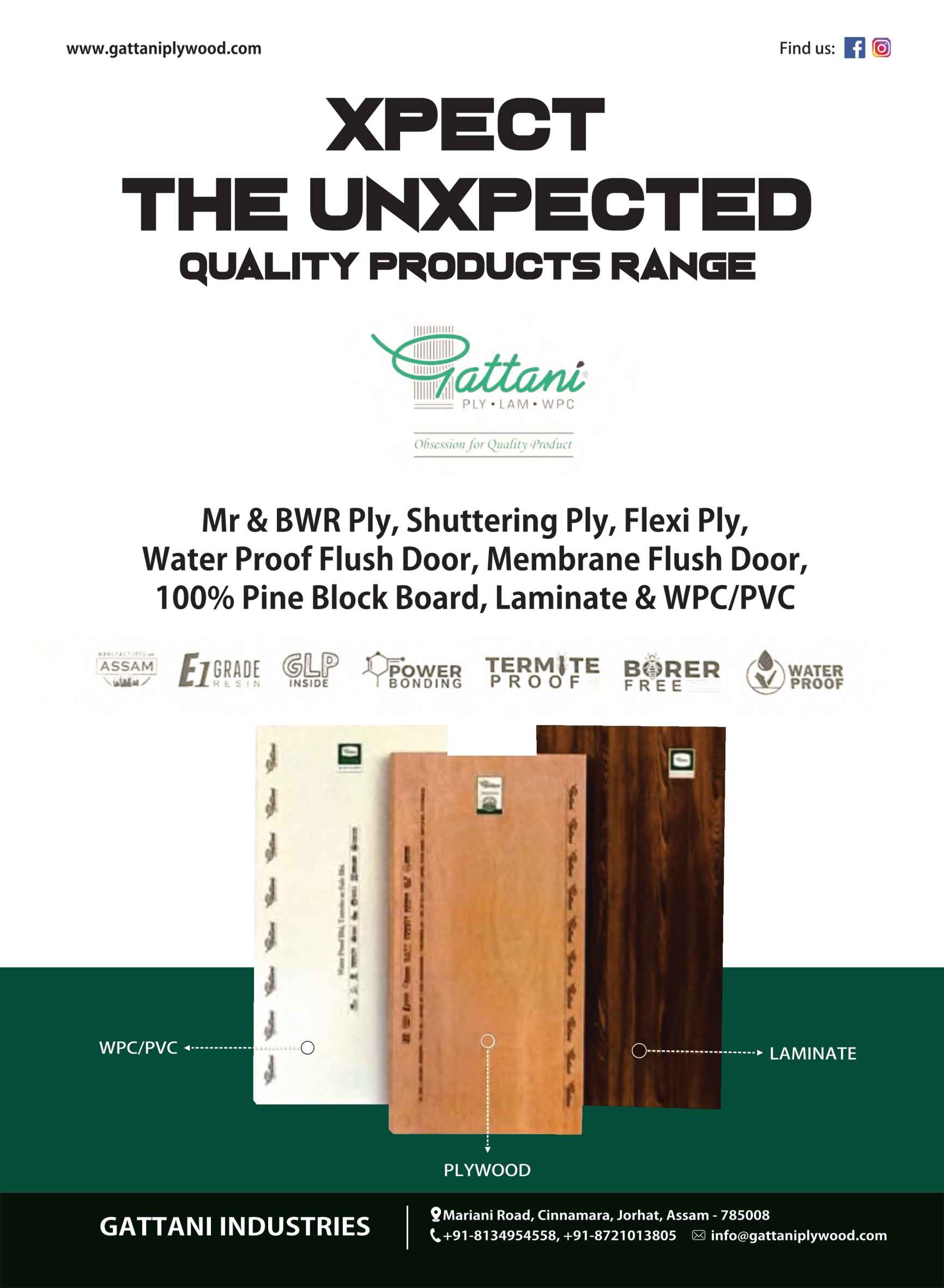

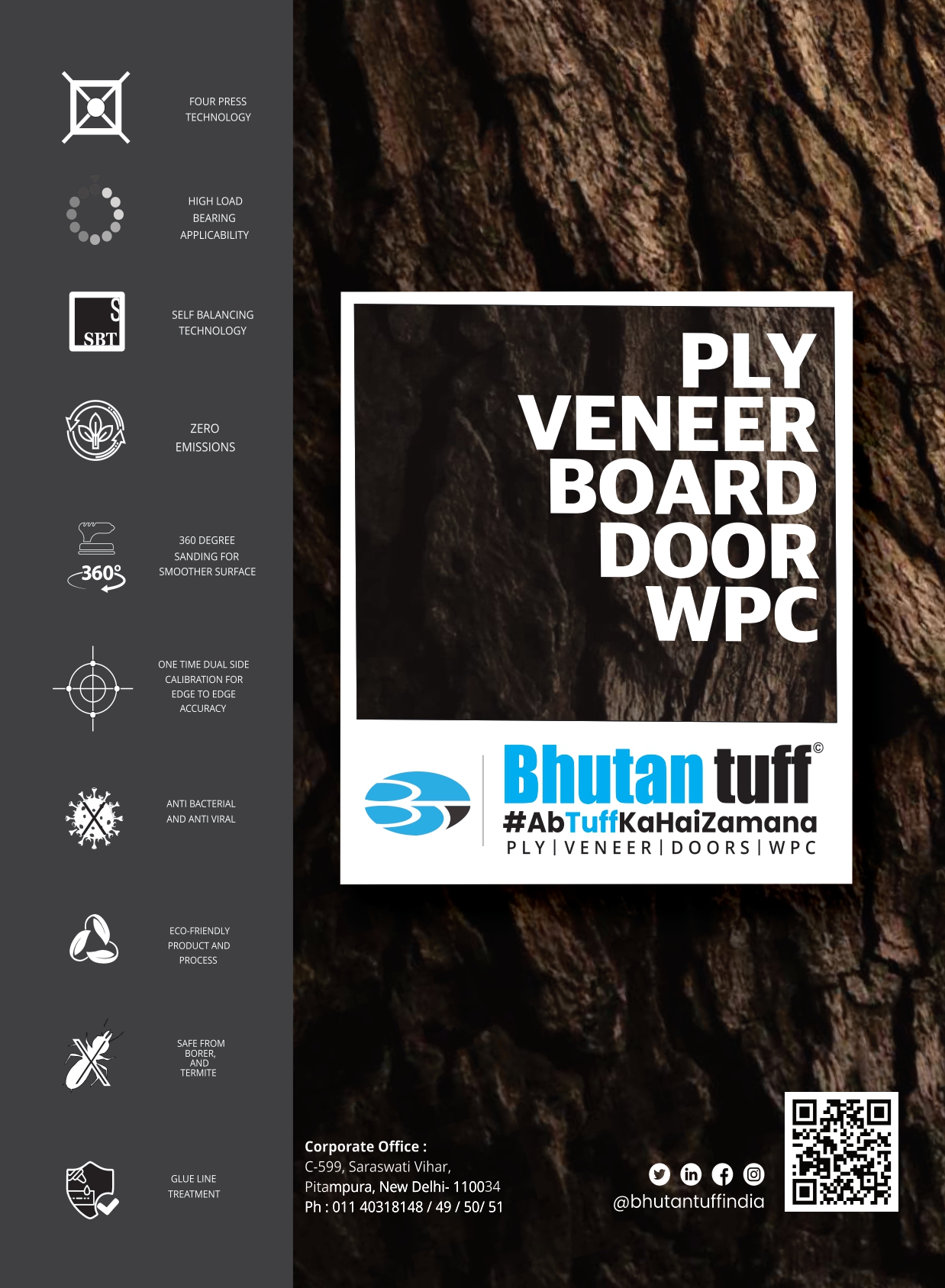

Plywood is an engineered wood sheet material made up of fine layers or flimsy strands of wood veneers attached together placing wood grains 90 degrees to one another. It is one type of manufactured board which can be described as a mixture of Medium Density Fibreboard (MDF) and Chip Board (Particle Board). It is a posh material and attaches organic compound and fiber sheets of wood.

Plywood flooring has become popular through this decade because it’s relatively low moisture content which makes various tasks easy to perform with this. Mostly for outdoor uses plywood has become very important to use. The renowned British powerboat company uses plywood flooring for the construction of Motor Torpedo Boats and Motor Gun Boats.

Following are the various kinds of Plywood flooring.

- Softwood Plywood

- Hardwood Plywood

- Tropical Plywood

- Aircraft Plywood

- Decorative Plywood

- Flexible Plywood

- Marine Plywood

A brief description of these types of plywood is given below:

Softwood Plywood

Softwood Plywood which is also known as spruce-pine-fir or SPF because it’s from spruce, pine, and fir. Though it can be made from cedar (Cedrussp), douglas fir (Pseudotsugan menziesii). If made from spruce (Picea sp) the prominent grains are coated by a system so that this kind of plywood flooring becomes more effective as hard as concrete and used for shuttering strands and construction.

Hardwood Plywood

Hardwood Plywood is made from angiosperms. This sort of laminate is known by its solidness, hardness on surface, firmness, resistance quality. This can be used to bear heavy weight. Contact us to know about India’s best Laminate Manufacturers.

Tropical Plywood

Different types of timbers of tropical area are mixed to make this type of plywood. Though previously it was only collected from the Asian region, now also from Africa and America it is collected. Tropical plywood flooring in style for a few special qualities like

- Strength

- Density

- Evenness

- Inflexibility

- Resistance quality

- Thickness

South Asia being tropical region manufactures plywood most. Countries like Japan, Thailand, Taiwan, Korea, Dubai and even in America, England this type is used. The bad impact of this type is that for extreme production of this type deforestation is becoming a great problem for some countries like Malaysia, Philippines, Indonesia because of these countries export plywood worldwide. Especially Malaysian laminate is thought as Malaysian board in the People’s Republic of Bangladesh and large in style among bangladeshies due to its higher thickness. Their are number of Laminate Manufacturers in India who supply this type of laminate.

Aircraft Plywood

Woods from Mahogany (Swietenia Macrophylla), Spruce (Picea sp.), Birch (Betula sp.) are used to make Aircraft Plywood. The African mahogany gives usable structural aircraft plywood. Among birch trees European birch is good. This type is famous for strength. This type is additionally made of Mahogany, Spruce, Birch but the special quality is that this is resistant to heat.

Decorative Plywood

Decorative plywood is also called overlaid plywood. Usually made from woods of ash ( Fraxinus sp), oak (Quercus sp.), Red oak (Quercus rubra), birch, Maple (Acer sp), mahogany, Philippine mahogany also called seraya, rosewood ( Dalbergia sisso).

Flexible Plywood

Flexible plywood because the name goes versatile laminate is employed for creating the versatile article of furniture or structures. These are made from Baltic Birch ( Betula sp).

Marine Plywood

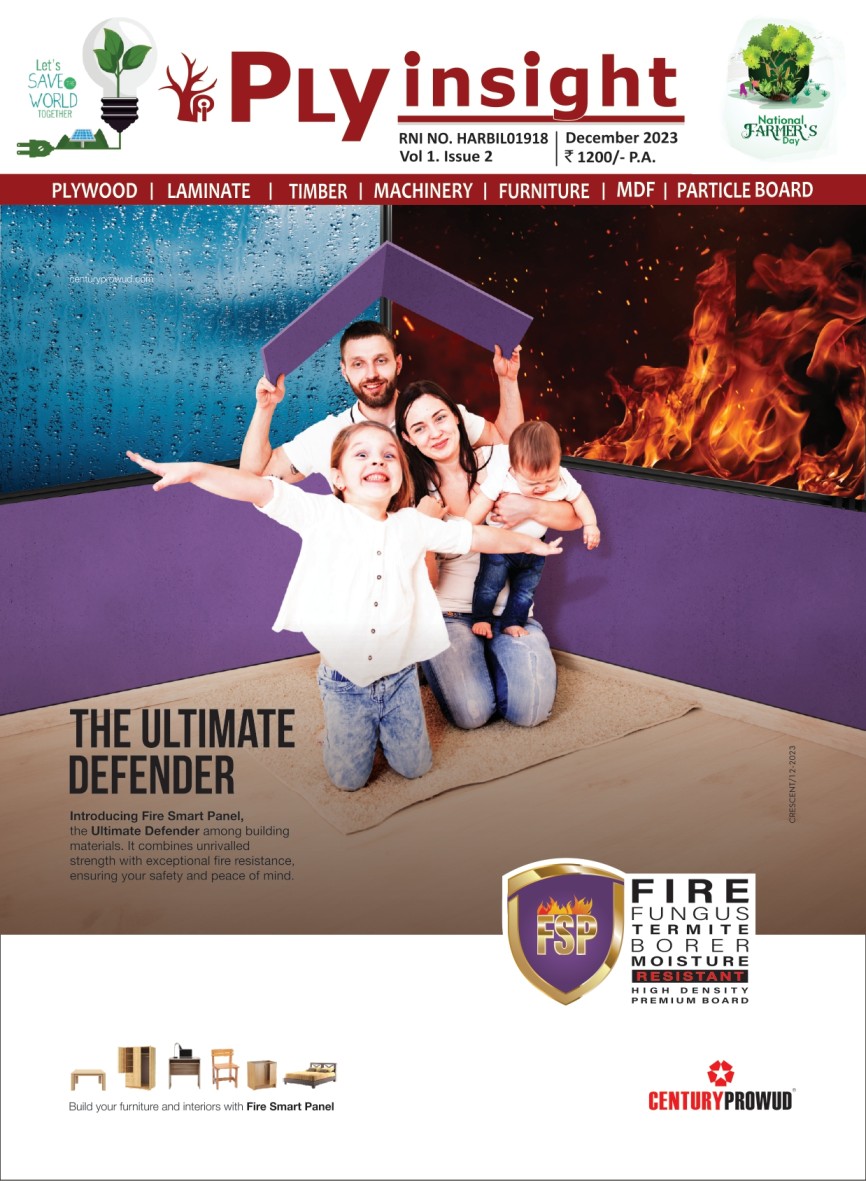

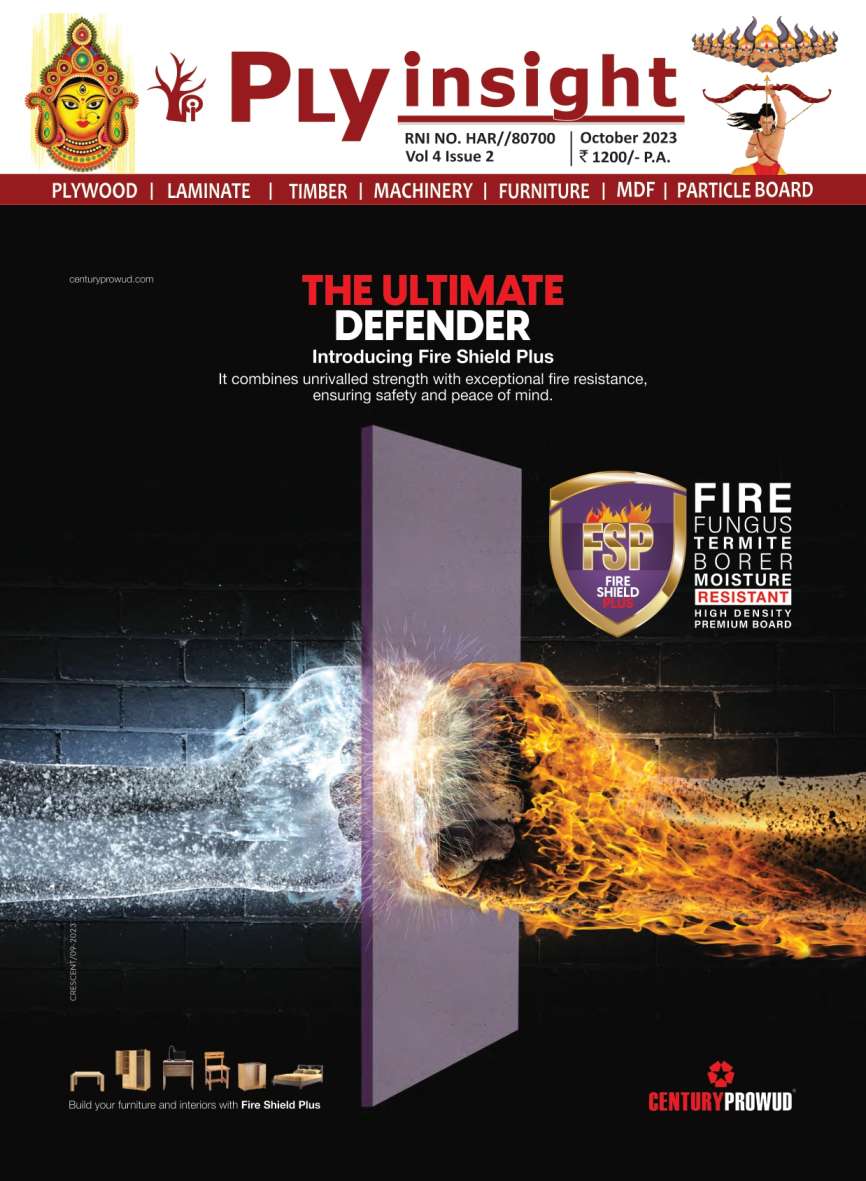

The type of plywood which can be used in moisture, humid, wet environment is called marine plywood. Even it will be employed in wet for the long amount. The layers of marine plywood flooring bear too small core gap to feel that doesn’t permit the wood to fix water inside the gaps. It is also fungal resistant.

Some plywood manufacturers are Sri Balajee Industry (Kathputli), Century Plyboards (India) Limited, Damodar Plywood, Gennext Plywood (P) Limited, Globe Panel Industries India Pvt. Ltd., Northern Plywood and Laminates, Empire plywood Industry, M.P.Veneers Pvt.Ltd., Krishna Decoratives, Alakhnanda Plywood Industries (P) Ltd., United Timber Products (Harpa), J.K. Ply & Décor (Purodecora), Chander Sagar Timber Product (Berlina), Maharaja Aggarsain Udyog (Donar)

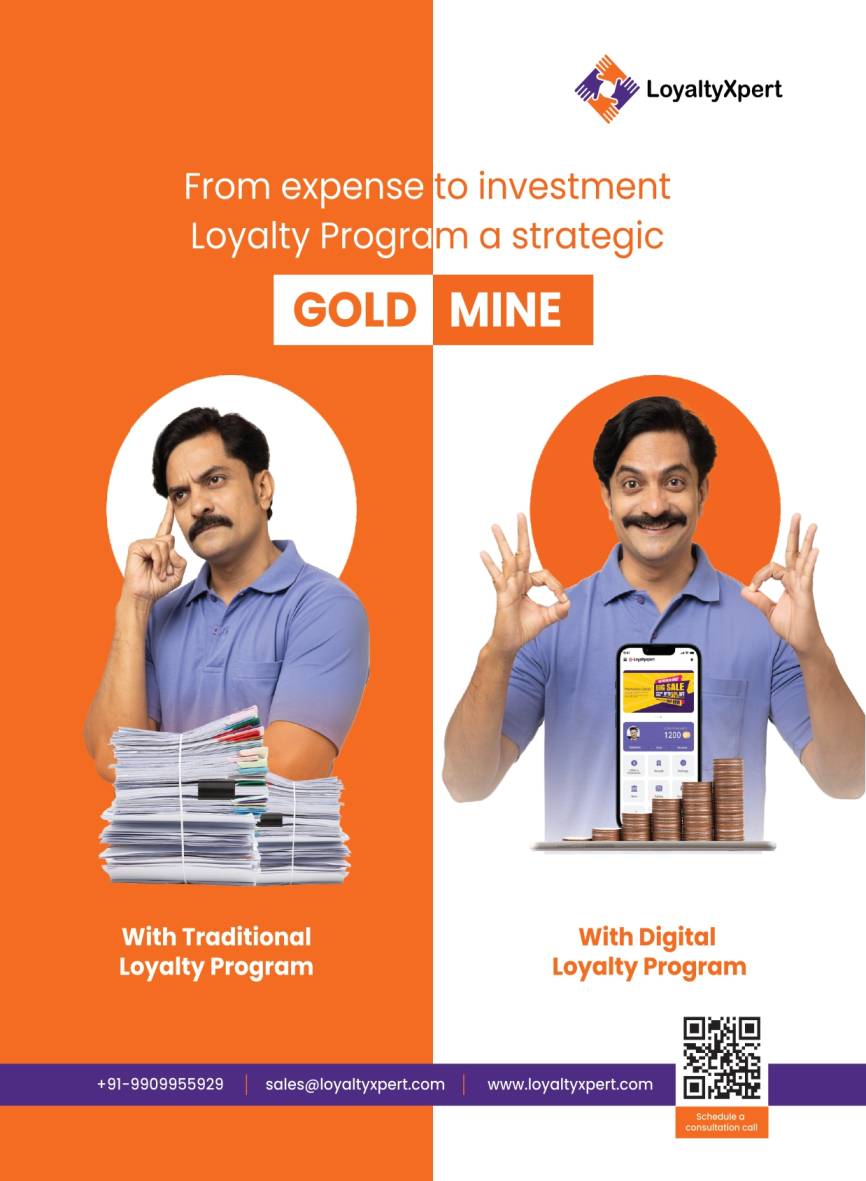

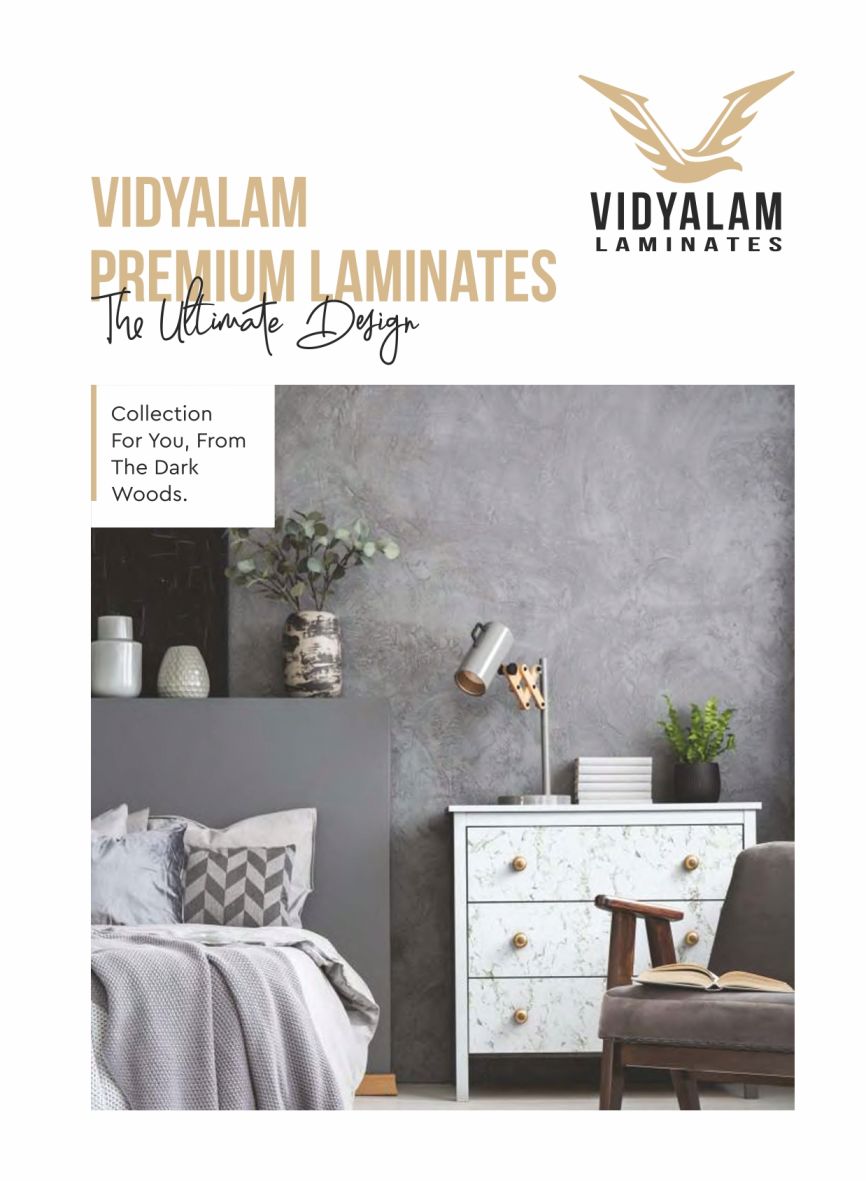

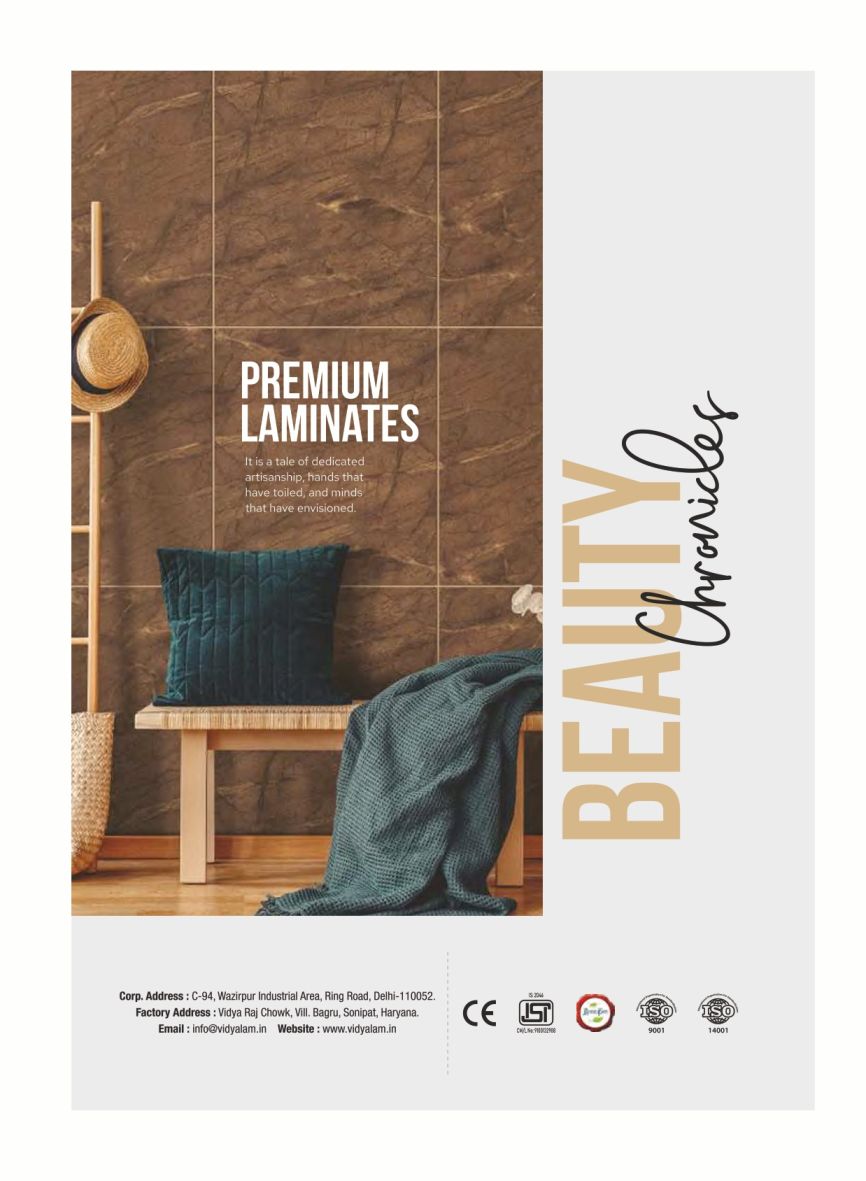

Laminate Manufacturers/Flooring

Laminate flooring (also referred to as floating wood tile within the United States) may be a multi-layer artificial flooring product consolidated along with a lamination method. Laminate flooring simulates wood (or typically stone) with a photographic applique layer below a transparent protecting layer. The inner core layer is sometimes composed of synthetic resin and fiberboard materials. There is a European Standard No. EN 13329:2000 specifying laminate floor cover necessities and testing ways. Follow Plyinsight Monthly Magazine to know about best Laminate Manufacturers in India.

Laminate flooring has grownup considerably in quality, perhaps because it may be easier to install and maintain than more traditional surfaces such as hardwood flooring. It may even have the benefits of cost accounting less and requiring less ability to put in than different flooring materials. It is moderately sturdy, hygienic (several brands contain an antimicrobial resin), and relatively easy to maintain.

Installation

Laminate floors are reasonably easy for a DIY homeowner to install. Laminate flooring is prepackaged as a variety of tongue and groove planks, which can be clicked into one another. Sometimes a glue backing is provided for ease of installation. Installed laminate floors typically “float” over the sub-floor on top of a foam/film underlayment, which provides moisture- and sound-reducing properties.

A small (1–10 millimetres (0.039–0.394 in)) gap is required between the flooring and any immovable object such as walls, this allows the flooring to expand without being obstructed. Baseboards (skirting boards) can be removed and then reinstalled after laying of the flooring is complete for a neater finish, or the baseboard can be left in place with the flooring butted into it, then small beading trims such as shoe moulding or the larger quarter-round moulding can be fitted to the bottoms of the baseboards. Saw cuts on the planks are typically needed at edges and around the cabinet and door entrances, but professional installers typically use door jamb undercut saws to cut out space to a height that enables the flooring to travel below the door upright & casing for a cleaner look.

Improper installation can result in peaking, in which adjacent boards form a V shape projecting from the floor, or gaps, in which two adjacent boards are separated from each other.

Care

Every Laminate Manufacturers makes necessary to stay laminate clean, as dust, dirt, and sand particles may scratch the surface over time in high-traffic areas. It is additionally necessary to stay laminate comparatively dry, since sitting water/moisture can cause the planks to swell, warp, etc., though some brands are equipped with water-resistant coatings. Water spills aren’t a retardant if they’re wiped up quickly, and not allowed to sit for a prolonged period of time.

Adhesive felt pads are typically placed on the feet of an article of furniture on laminate floors to forestall scratching.

Inferior glueless laminate floors could step by step become separated, creating visible gaps between planks. It is necessary to “tap” the planks back along with exploitation the acceptable tool as gaps ar noticed so as to forestall dirt filling the gaps, thus making it more difficult to put into place.

Quality glueless laminate floors use connection mechanisms that hold the planks along below constant tension that stops dirt coming into the joints and don’t want “tapping” back along sporadically.

Some Laminate Manufacturers are Star Laminates Pvt.Ltd., Vidya Lamtech LLP, Northern Plywood and Laminates, Trikalp Laminates India Pvt.Ltd.