MASTERING IS 303: STRATEGIC INSIGHTS INTO Plywood Testing, Standards, and Industry Impact (Part-3)

- September 9, 2024

- 0

Dr. Anand Nandanwar: Scientist ‘F’, PPPT Division, Institute of Wood Science & Technology, Bengaluru

99% of plywood can pass E2 grade and new specifications:

The specifications of Plywood in BIS were made in 1989, which has now been amended in 2024.

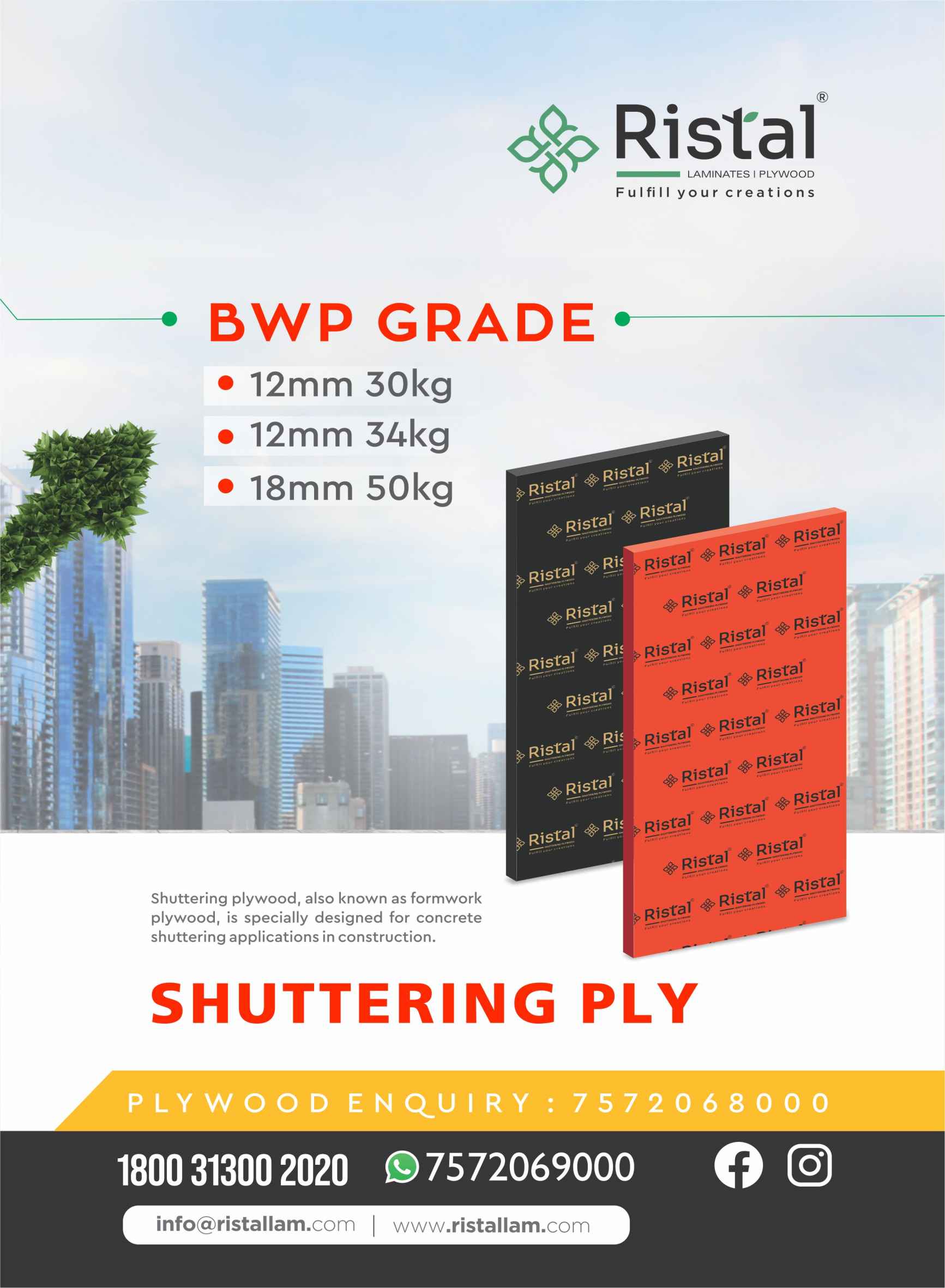

Now BWP grade has been included in IS 303. The main reason for this was that IS 710 or IS 4990 was being used for interiors as well. Whereas these grades were made for use in marine or shuttering. Where high value strength is required. By including BWP in IS 303, it can now be used even in places of damp or harsh environment.

The value of along the grain in MOR and MOE has been reduced by 15%, for which the value of across the grain has been increased to compensate. So that there is no need to compromise much in end use application.

Thirdly, we have included E1 and E2 grades for emission. I believe that 99% of plywood can pass E2 grade.

In this way, these amendments of 2024 have become more manufacturer friendly.

Earlier, there were only types A and B for the surface, which had a limitation of knots or crack defects, additionally, now type C has also been included. In this, the restriction on the number of defects has been removed with the consent of the manufacturer and the buyer.

Apart from this, a very big change, which people are having difficulty in understanding, is that’s we have brought the category of 303 in a range. Earlier there was a minimum Quality requirement, which had to be achieved. Now it has been divided from a range of 10 to 50. Now you can make ply in whatever range you want, by marking in that range and get it passed. Because whatever range of ply you are making, it cannot fail in terms of strength now, provided you have declared it accurately.

In engineering, modulus of rupture is noted as F and modulus of elasticity is called E. Now, if the MOR value of your ply is between 10 and 20 (say 15), then it will be called F 10. Similarly, if the value of MOE is between 10-20, then it will be called E 10.

Now, according to the strength of your ply, you can write and sell it as F 10 E 10 or F 10 E 20. However, this is the absolute lowest. Plywood cannot be manufactured below this strength.

Now, whatever strength you make of ply, you will be able to sell it in the market easily with BIS marking. You will only have to declare (marking) in which range it has been passed. In this, F 50 E 50 will be the highest range.

On the similar lines, changes have been made in MOR MOE in IS 710 and 4990. Standards are amended, in coordination of requirements of producer, technologists and consumer.

Standards are never fixed. They keep changing and will keep changing in future too. They need to be changed according to the needs of the market and the conditions of raw materials. But the main objective is that the consumer should get a quality product.

With BIS marking, a consumer who may not know about the basies of product, gets the assurance of a quality product. This assurance is the dignity of BIS.

Apart from this, a lot of work is going on in IWST on Block Board and Preservative Chemicals. Which will be published at appropriate time.

- Suresh Bahety

We can perhaps understand this better by the example of soap. First there is classification of Bath and Toilet Soap. After that there is grade 1-2 or 3 and finally TFM (Total Fatty matters) which is written in percentage. The minimum TFM in grade 1 should be 76 percent, 70 percent in grade 2 and 60 percent in grade 3. Now in this grade 3 TFM can be 60 percent and 65 or more. In a survey of almost all soaps available in the market, it was found that the actual results of TFM of almost all were more than the TFM declared by them.

- Anand Nandanwar

Apart from the specification (plywood for general purpose) in the marking, grade (MR or BWP) and the value of MOR/MOE will have to be written.

- Manoj Gwari Secretary & Treasurer Wood Technologist Assoc. Technical Consultant BIS

New specification of IS303 has been published, it has now been divided into three categories. In addition to MR and BWR, now the third one BWP has been added. Similarly, C has been added in face veneer which used to be A and B only.

By creating F10 to F50 in MOR/MOE, a cambo of (25) five into five categories has been created.

This is very confusing. There will be a problem in this five into five combo. If someone by mistake or intentionally sells F 20 or F 30 grade by putting F 50 (on the market demand), then now clause of stop marking, may be exercised. In this way it will save us in classification of below standard products but from the BIS point of view, it can create problems in sampling.

👇 Please Note 👇

Thank you for reading our article!

If you don’t received industries updates, News & our daily articles

please Whatsapp your Wapp No. or V Card on 8278298592, your number will be added in our broadcasting list.