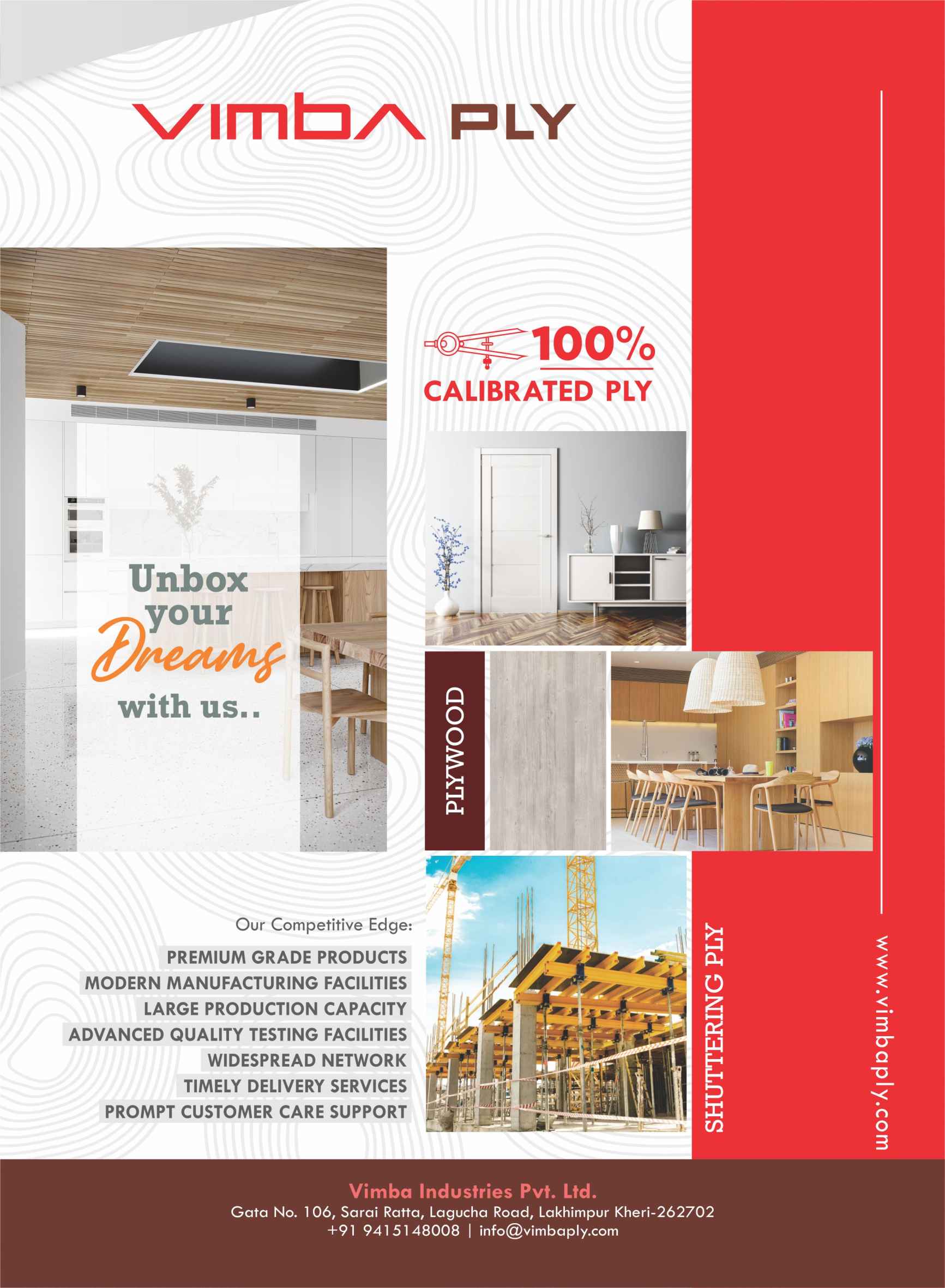

Benefits of Calibrated Plywood and It’s Uses

- April 11, 2024

- 0

Understanding Calibrated Plywood: Benefits and Applications

As the pleased proprietor of a flourishing pressed wood fabricating organization, I’ve seen the development of different pressed wood items throughout the long term. Among these, aligned pressed wood stands apart as a wonderful development that has changed the carpentry business. In this article, we’ll dig into what aligned compressed wood is, its various advantages, and its different scope of utilizations.

What is Calibrated Plywood?

Calibrated plywood is a specialized type of plywood that undergoes precise machining to achieve uniform thickness across its entire surface. Unlike traditional plywood, which may exhibit slight variations in thickness due to manufacturing inconsistencies, calibrated plywood ensures consistent thickness with minimal deviations.

This accuracy is accomplished through cutting edge fabricating procedures, including best in class apparatus and severe quality control measures. Each sheet of aligned compressed wood is fastidiously adjusted to satisfy demanding guidelines, bringing about a result of extraordinary quality and consistency.

Benefits of Calibrated Plywood

The benefits of calibrated plywood are manifold, making it an ideal choice for a wide range of woodworking projects. Here are some key advantages:

Uniform Thickness: The essential benefit of aligned pressed wood is its uniform thickness. This consistency guarantees dependability and consistency during the development cycle, permitting specialists to work with more noteworthy accuracy and precision.

Smooth Surface: Aligned compressed wood normally includes a smooth, faultless surface that is liberated from blemishes like knocks, imprints, or voids. This perfection not just improves the stylish allure of the completed item yet in addition works with simpler getting done and painting.

Further developed Execution: On account of its uniform thickness and top notch development, adjusted pressed wood offers better execution thought about than customary compressed wood. It shows more prominent strength, toughness, and dependability, making it appropriate for requesting applications where underlying honesty is fundamental.

Cost-Viability: While aligned pressed wood might be somewhat more costly than standard compressed wood, its various advantages legitimize the speculation. The reserve funds acquired from decreased squander, further developed productivity, and upgraded life span offset the underlying expense, pursuing it a savvy decision over the long haul.

Flexibility: Adjusted pressed wood is unbelievably adaptable and can be utilized for a large number of uses, from furniture making to inside getting done, cabinetry, and design carpentry. Its predictable thickness and great development make it a vital material for experts and fashioners looking for solid execution and extraordinary outcomes.

As per a source from 2018, the Indian compressed wood section’s market size was around 2.5 Billion USD, with a huge piece (more than 70%) being overwhelmed by chaotic players (Source: Conforsply – Request and Fate of Aligned Compressed wood in India). This proposes there’s space for coordinated players zeroing in on adjusted pressed wood to build up some momentum.

Utilization of Aligned Compressed wood

The adaptability of aligned compressed wood fits a broad cluster of uses across different businesses. A few normal purposes include:

Furniture Making: Calibrated plywood is widely used in the manufacturing of furniture, including tables, chairs, cabinets, and shelving units. Its consistent thickness and smooth surface make it an ideal choice for creating sleek, modern designs with clean lines and impeccable craftsmanship.

Cabinetry: Calibrated wood is a well known decision for building kitchen cupboards, restroom vanities, and capacity units. Its solidarity, sturdiness, and layered soundness make it appropriate for supporting weighty loads and enduring the afflictions of day to day use.

Inside Wrapping up: In inside plan and development, adjusted compressed wood finds applications in wall framing, roof medicines, and improving millwork. Its uniform thickness and smooth surface give an ideal material to different completing procedures, including painting, staining, and veneering.

Architectural Woodworking: Architects and designers often specify calibrated plywood for architectural elements such as doors, partitions, and built-in furniture. Its consistency and reliability ensure seamless integration with other building materials, resulting in cohesive and visually appealing interiors.

Specialized Applications: Beyond traditional woodworking projects, calibrated plywood is also used in specialized applications such as boat building, aircraft interiors, and exhibition displays. Its exceptional quality and performance make it a preferred choice for projects that demand precision and reliability in challenging environments.

In conclusion, calibrated plywood represents a significant advancement in plywood technology, offering unmatched consistency, quality, and versatility. Whether you’re a seasoned craftsman, a furniture designer, or an architect, calibrated plywood provides the perfect combination of performance and aesthetics for your next project.With its various advantages and different scope of uses, adjusted compressed wood keeps on moulding the eventual fate of carpentry and development enterprises around the world.

👇 Please Note 👇

Thank you for reading our article!

If you don’t received industries updates, News & our daily articles

please Whatsapp your Wapp No. or V Card on 8278298592, your number will be added in our broadcasting list.