An Understanding of WBI of Vietnam and Nepal

- April 11, 2024

- 0

A team of wood Technologists Associan recently visited Vietenam and Nepal, headed by Gajendra Rajput, vice President and associated by Manoj Gwadi, Secretary & treasurer and Avdhesh Yadav, Secretary. The tour was conducted to study the working style of these industries along with the characteristics of different species of timber used by them.

More than seven companies of vietnam were visited by the WTA team. Gajendra Rajput told that working methods is very much different there in comparison to India.

Engagement of worker is just one fourth of India, due to Automatic Production line as well as adoption of cold process method in production. You will be surprised to know that almost every plant is producing plywood through pre press technology.

Primarily, two species of wood is utilised in abundance in Vietnam. One is Acacia and the other is Eucalyptus (safeda). While eucalyptus provides density to the material, acacia, which is a wood almost similar to poplar, helps in increasing the elasticity of the material.

The process of peeling wood is same as in our country but after simply sun drying the veneers, assembly of the material starts with about 12&14 percent moisture in core. Dryer (machines) is used rarely in any factory.

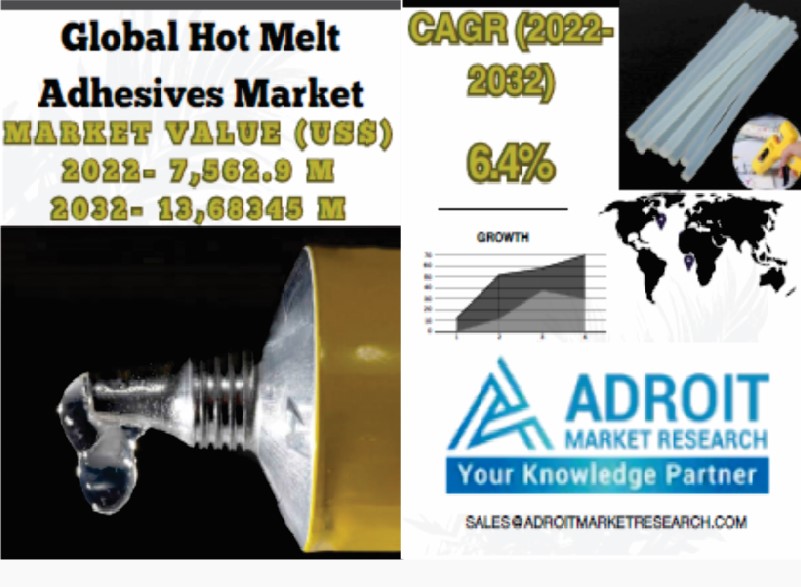

Manoj Gwari told that the assembly of the core veneer is done by spreading glue directly on the conveyor line and utilization of this moist core is possible due to their special MUF resin. The MUF resin in Vietnam is similar to our MR grade resin, but few other chemicals are mixed in the resin to absorb moisture, which makes it possible to assemble and pre-press even moist cores. After pre-pressing, the goods are pressed in the hot press for a certain period of time only and the goods reach the final stage with a good finish.

Manoj Gwari told that the assembly of the core veneer is done by spreading glue directly on the conveyor line and utilization of this moist core is possible due to their special MUF resin. The MUF resin in Vietnam is similar to our MR grade resin, but few other chemicals are mixed in the resin to absorb moisture, which makes it possible to assemble and pre-press even moist cores. After pre-pressing, the goods are pressed in the hot press for a certain period of time only and the goods reach the final stage with a good finish.

If you compare the basics of Vietnam with our country, you will realize that they are able to produce goods at much lower rates than us, the main reason for which is the difference in resin only. If we adopt and use this type of resin in our country also, we can get benefits by making good quality MUF grade material with high productivity.

Most of the companies having capacity of two to five presses use only three tonne boiler and ensure their profit by saving maximum energy during plywood production.

As you all know that wood Technologists Associan is a group of experts related to plywood industries, so if any Indian WBI wants any kind of cooperation in this regard, they can directly contact Mr. S.C. Jolly, president WTA.

As you all know that wood Technologists Associan is a group of experts related to plywood industries, so if any Indian WBI wants any kind of cooperation in this regard, they can directly contact Mr. S.C. Jolly, president WTA.

As far as Nepal’s perspective is concerned, plywood is being produced there in the Indian style., because poplar wood is available in very limited quantity, Utis, a native wood species of Nepal, is used, which is slightly less stronger than poplar but is a useful wood. Its specialty is the smoothness it gets after drying due to the softness of its fiber, which provides a beautiful finish to the product after it is applied on the top layer of the product. There is no significant change in other areas of production except some technology issues in Nepal and WBI.

👇 Please Note 👇

Thank you for reading our article!

If you don’t received industries updates, News & our daily articles

please Whatsapp your Wapp No. or V Card on 8278298592, your number will be added in our broadcasting list.