BIS’s Awareness Program on Quality Control Orders

- September 12, 2023

- 0

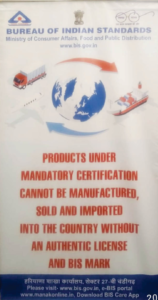

The Haryana branch office of the Bureau of Indian Standards recently organized an awareness program on quality control orders for wood products.

During the program, plywood manufacturers expressed concerns about the fate of sub standard plywood manufactured in the process after the mandatory implementation of BIS standards. They wondered if they would have to discard these plywood.

In response, Saurabh Tiwari, the Director and Head, BIS, clarified that this would not be the case. When setting the standards, it will be ensured that different categories of plywood have different standards. The goal is to ensure that manufacturers receive a fair price for their products, while consumers also get products that match the quality for which they are paying. All these concerns will be addressed while revising the BIS standards.

In response, Saurabh Tiwari, the Director and Head, BIS, clarified that this would not be the case. When setting the standards, it will be ensured that different categories of plywood have different standards. The goal is to ensure that manufacturers receive a fair price for their products, while consumers also get products that match the quality for which they are paying. All these concerns will be addressed while revising the BIS standards.

He further said that obtaining a license for IS. 1659 for Block Board is mandatory from August 10, 2023 as per Gazette notification. It sets a deadline of 6 months for large units, 9 months for medium-scale industries, and 12 months for small-scale industries.

The Director and Head of the Bureau, Sourabh Tiwari, revealed that the Bureau has developed an app. With this app, a consumer can scan the ISI number and determine whether the brand is genuine or counterfeit whenever they purchases any product from the market. If the brand is fake, a complaint can be registered through the app. The Bureau will take substantial action against such sellers. He also appealed to all manufacturers to obtain a BIS license or maintain the license.

Responding to concerns from the manufacturers, he stated that if any product is being sold in the market with a fake ISI mark, consumers also need to be vigilant. However, this awareness will gradually arise when consumers will realize the benefits of quality products. He added that the process of setting quality standards is in its initial phase, and once the first phase of mandatory license is complete, strict actions will be taken against those producers who are manufacturing low-quality goods without a BIS license.

J.K. Bihani, President of the Haryana Plywood Manufacturers Association, mentioned that the plywood industry in Haryana is currently facing tough times. Many units are shutting down rapidly, and those still operating are struggling.

J.K. Bihani, President of the Haryana Plywood Manufacturers Association, mentioned that the plywood industry in Haryana is currently facing tough times. Many units are shutting down rapidly, and those still operating are struggling.

BIS will not be bound by the standards. This could lead to the takeover of the market by low-quality, cheap plywood. If this He further said that all registered units under BIS will be required to follow the rules, while those not registered with is not regulated, both consumers and adhering manufacturers might be pushed out of the market. Manufacturers adhering to the standards will have to focus on quality, which increases production costs. Neither consumer is aware of quality standards nor is the market ready to accept it.

S.C. Jolly President, Wood Technologists Association stated that, Those who are licensee will constantly be under the threat of enforcement, while manufacturers who don’t take license will freely sell cheap, low-quality plywood in the market. In this entire scenario, it’s important to consider how manufacturers striving to meet standards can succeed. Without addressing this issue, it’s challenging to ensure the appropriateness of mandatory BIS standards. Additionally, how exercised over the quality of imported cheap plywood will be controlled is an important issue.

Additionally, if a manufactured product of plywood or MDF does not adhere to BIS standards, what will be the method of selling these products? Otherwise, the cost of production will increase significantly; this is a state of confusion. Until this is clarified, industrialists will remain in a dilemma. There is also ambiguity regarding the manufacture of ply board made from waste generated during production.

Devinder Chawla, President of the All India Plywood Manufacturers Association, suggested that discussions should focus on how these standards can strengthen the industry. It is a challenging time for the industry. Currently, India is facing tough competition from countries like Nepal, Vietnam, China, Thailand, and others, who are dumping cheap plywood into our country. This poses a significant challenge for us. The rate is the most significant issue now. Cheap plywood floods the market, and consumers are looking for it.

Devinder Chawla, President of the All India Plywood Manufacturers Association, suggested that discussions should focus on how these standards can strengthen the industry. It is a challenging time for the industry. Currently, India is facing tough competition from countries like Nepal, Vietnam, China, Thailand, and others, who are dumping cheap plywood into our country. This poses a significant challenge for us. The rate is the most significant issue now. Cheap plywood floods the market, and consumers are looking for it.

The critical point is that the standards are still based on standards set fifty years ago when plywood was made from timber harvested from forests. Nowadays, plywood is made from wood harvested after three to seven years of farming. If the BIS standards are not revised, it will destroy the industry, he added.

S.C. Jolly, President of the Wood Technology Association, emphasized the need for such programs to be held regularly to facilitate communication between manufacturers and authorities, which is essential for the industry.

During the meeting, plywood manufacturers also called for revisions in the standards for Marine Plywood (IS 710) and Shuttering Plywood (IS 4990) to make them more industry-product- friendly. Everyone desires quality, but it can only be achieved when there is a broad market awareness and effective competition strategies.

The program was inaugurated by Madan Singh Chauhan, the Mayor of Yamunanagar, who stressed the importance of instilling confidence in plywood and wood product manufacturers while making changes to standards. He stated that meaningful results can only be achieved when manufacturers and the BIS nave mutual understanding.

Pranav Chandra, President of the Yamunanagar-Jagadhri Chamber of Commerce and Industry, also participated in the meeting.