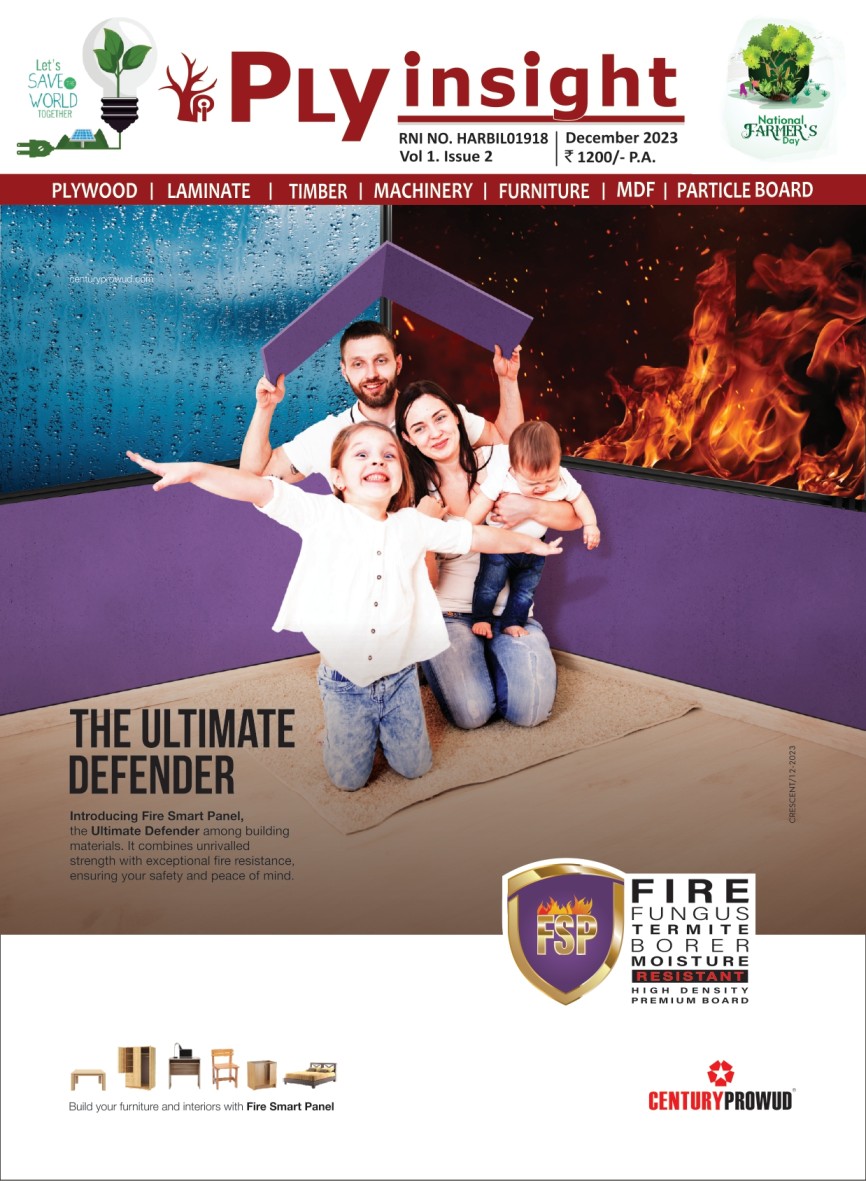

Quality & Consistency for Conforming to QCO Standards in the Plywood Industry

- May 8, 2024

- 0

MP Singh

India is now becoming aware of quality control. India is working for zero defect products. Quality and Conssistency for conforming to Standards in the Plywood Industry Products, that’s why, QCO has been implemented. One year’s time has been extended for it. Now everyone have a chance, to complete their preparations. And whatever changes or, preparations are to be made, can be done easily.

Consumers will get a lot of benefits from QCO. They will get a defectless quality product. The industry will also benefitted. Because now they will have to make the quality according to the preseribed quality standard of the product. Neighboring and those countries who have to export goods to India will also have to maintain this quality.

Indian and foreign plywood manufacturers will have to conform the quality of plywood as per BIS standards.

Indian plywood Consumes timber from agroforestry. The source as well as properties of the wood used by plywood and wood manufacturers of Nepal and Vietnam, should be discussed in detail.

CN Pandey

CN Pandey

QCO has brought an opportunity for the industries to improve their quality. Although we missed out on capitalizing on this opportunity earlier, now we will make an effort collectivity so that we can take advantage of this opportunity.

When the QCO was announced, there was an uproar in the industry. Everyone was desperate in the plywood industry. This question was repeatedly being raised that what will happen to rejections or the product that does not fulfill the set standards? Because such products were estimated at ten to 15 percent. When the technical committee used to meet with the Director IWST regarding this, it was discussed regularly about the fate of the product that does not quality the quality standards?

Because if it cannot be sold in the market then the production cost will increase. Keeping it in mind, we conducted several webinars. Discussed with the technical committee. Problem was discussed and possible solutions searched.

Many points came to light in this

Different types of wood are being used in every area, its quality is different, because the species are different.

Every wood has its own specific properties and elements. Hence, the quality of the plywood product produced in different regions will also vary. In such a situation, how can a standards be prepared so that products can meet the quality standards made from every types of wood.

- Raw material is relatively cheaper at some places. That’s why; the production cost can be less or more.

- Fluctuation in prices is also a big challenge. In an attempt to reduce the production cost, quality may be compromised.

It was observed that the standards are very old, about 20 to 25 years old standards. There was a urgent need to change them. Going for this change, extensive discussions were held with plywood producers, and experts. Its purpose was to set a standard that would cater the suitability for plywood manufacturers across the country. Plywood manufacturers across the country shared their suggestions. We took views from all over the country including Yamunanagar, Punjab and Uttar Pradesh. In this, it was kept in mind that the quality should be prepared to a minimum required level. Although there are still some shortcomings in it, improvements can be done gradually from time to time. It is the result of one year of hard efforts that we have a satisfactory quality standard.

Our effort is that whatever product comes in our market now, it should match with the prescribed standards. The norms for formaldehyde emission is also included in it. But it was also tried that the industrialists can easily fulfill these standards.

When the QCO was about to be implemented, many associations demanded that it should be extended. Because many units are still outside the BIS purview. Therefore, one year’s time was granted. One year is more than enough. In this period we can avail BIS certificate and make our product compliant with the standards.

The problem now is that the industrialists have slowed down the process just to wake up before the finall call. As far as Nepal’s plywood is concerned, how much their product stands on the BIS quality, it will be known only after testing. They will face more technical problems, which is just natural.

The question is why do we make standards? The idea behind this is that there should be a standard for quality. So that consumers can get products of appropriate standards easily.

Consumers are not yet aware enough to decide the quality themselves. Therefore, there is a need to make such standards. So that consumers can buy quality products with confidence.

Therefore, industrialists should start to maintain their Quality according to these standards as soon as possible, because there is not much time left.

Standards for MDF and particle board are also going to be finalised now. As far as the ten percent sub standard products that do not meet the set standards, no final decision has been arrived at.

Given the changes made in BIS, the quantity of rejection is likely to decrease.

Hom Prasad Ghimire: India and Nepal have a lot of similarities in art, culture and lifestyle and are connected to each other. Many companies of India have invested in Nepal. Who have a big role in the power sector and service in Nepal.

Nepal imports all kinds of remaning products in raw material as well as plywood machines from India except wood. But Nepal’s plywood has a big market in India. We respect India’s quality standards. To meet these standards, we have applied for registration. However our unit has not been inspected yet. There are around 70 units in Nepal, which are smaller than any average factory in India.

Nepal imports goods worth ten thousand crores from India, but is exporting only one thousand crores to India. Plywood is a very small part of it. Still, the standards set by India will have to be adopted. We accept every policy of India. We will try our best to produce plywood according to Indian standards.

Champalal L Bothra: Nepal is keen about BIS. The industrialists here are also aware of quality. We have already applied for the registration of our unit. Plywood worth two hundred crores only is exported from Nepal to India. Our problem is that we have applied for the certificate in BIS. But till now no inspection has been done by BIS.

MP Singh: From where do you procure timber?

Champalal L Bothra: Uttis is cultivated on the hills. Now the cultivation of Safeda and Poplar has also started here. Still, uttis is the main source of timber. Its density is around 500 to 600. Borer does not attack it. Because this wood grows along with herbs.

MP Singh: After how many years the wood is ready for harvesting?

Champalal L Bothra: This timber is harvested at five to six years. Its girth comes to 24 inches to 50-60 inches. It gives good surface finishing. Right now the core of this wood is being exported to India also.

Devanand Saraogi: With the implementation of QCO, many good things are going to be happen in the industry. Along with India, Nepal industry will also improve its quality and produce its products as per BIS. Most of our units have also applied for BIS. Laboratories have also been set up in all these units. But no intimation has been received from BIS for inspection or factory visit. Which is worrying us.

We would like to request BIS and the Government of India as well as the Indian public to treat Nepalese industrialists sympathetically.

As far as quality in Nepal units is concerned, all of them are capable today, they can produce products as per BIS standards. This will again benefit our industry in improving quality further. Nepal also has Nepal Standard as BIS. Is it possible for BIS to test the products here itself from the Nepal Standard?

We are already producing products as per Nepal standards. One of the other concern is that BIS laboratory is far away. If a laboratory is made in Nepal also, which can be run by technical experts from India. So that testing of our product is done fast.

New standards of BIS are also prepared. When will these new standards come? Where will our applications stand which are submitted earlier? Will it be accepted or not?

What will be the positive or negative impact of these new standards?

Please also shed light on how we can easily get the BIS certificate. What should we do for this?

MP Singh

MP Singh

This is an policy issue of two countries, which can be resolved between senior diplomats of two countries. Similarly, a decision for working together, of BIS and Nepal Standards can also be taken only at the top political level.

As far as matter of releasing new licence, Indian industrialists are also not getting it easily. Because BIS has been made mandatory for many products simultaneously. Because of this, such a large number of applications have been filed. That’s why it is taking time, which is a natural procedural fact.

When teams go to foreign companies for inspection, it may take extra time to get permissions etc. Therefore, you should try at your level. Talk to your leaders and officials.

Because at our level, we cannot be very effective in it. We can understand that you have labour, raw material. You are capable of making good products. As far as the system is concerned, it may take some time.

The new standards are being notified. As far as clarity on standards is concerned, there will be clarity in due course of time. The applications for grant of new licenses that have already been applied will not be adversely affected by this.

Abhishek Chitlangia:

India is going to become a global power. It is India’s pride that we are going to set quality standards in wood products. India can make products of international quality and put its products at the global level. Now we should expect that quality standards are implemented as soon as possible. If India has to use the wood of the world, then its qualities will have to be checked.

Products from Nepal and Vietnam have made deep inroads in India. The Indian market has no problem with the (good) quality products coming from abroad. The problem comes from those substandard products which disturb the market and cheat the consumers just because they are cheap. Such products are also produced in the country along with huge quantity of imports. We must have to put a check on such cheap products. And that’s why implementing QCO has become very necessary in the interest of the country.

The challenge is always there. We have to deal with it. Because when you develop individually, industry as a whole will develop. I think that the standards will be implemented within a year. It should not be that we apply at the nick of the stipulated time limit. We should start working from today itself. We should not ask for additional time now. However, the government has also clearly said that the producers will not be given any time relaxation hence forth.

CN Pandey

You can get the samples tested in a BIS recognized laboratory. IWST also has a recognized laboratory. You can get the product tested from it and get a certificate from the IWST.

MP Singh

This is definitely the first step. This must be done. It is better that you get the sample of your product tested and get its certificate.

There is very less probability that Nepal’s laboratory will get BIS recognition. Now we should just try to make the product as per the standards. To contact BIS, you will have to give this responsibility to someone. You will have to sign an MOU with them. Because this is a genuine and natural problem.

If we also want to sell our product in the US or Europe etc. from India, we also have to face such problem. Every country has its own way and policy, so there is always some obstacle in it.

Pramod Chaudhary: Any talks between the government to the government can take a lot of time. Therefore, whatever changes have to be made for the certificate, we are ready for it. A help desk should be set up in Delhi for the process of releasing the certificate. Which can make our certificate work easier. The industrialists of Nepal can get their product samples tested in the laboratory of Delhi.

The changes which have been made in the standards should be in public. It will take seven to eight months to get the license. I think our exports may be affected by this delay. In such a situation, what steps can BIS take at its level to facilitate us.

MP Singh: BIS is currently under tremendous work pressure. Suddenly a lot of applications are there. That’s why it is taking time. As because we cannot take your concerns to BIS. You should take your issues to BIS yourself. If you wish, you can take help from Plywood Association or Plywood Export Association.

As far as we are concerned, we can just speed up the testing of your sample. As far as change in standards is concerned, there is not much change in it. Things have been simplified a lot.

Srinivas: Goods worth 14 crores are being exported from Vietnam to India every month. Whenever there is a problem of raw material in India, Indian producers import raw material from Vietnam. Vietnam’s standards for export are compared with international standards. We have applied for BIS licence. We want this work to be made easy.

Manoj Gwari

The infrastructure of plywood industry in Nepal is satisfactory. They have a wood called Uttis. Which is more or less similar to poplar. Plywood prepared from this wood is more or less of good quality. Nepal Plywood Association, should arrange to collect scientific data and research of Uttis. So that it can be proved to all what are the qualities of Uttis? In India, there is a misbelief that Uttis wood is low in properties, which affects the quality of plywood. This myth can be eradicated. Eucalyptus is also being cultivated now on a large scale in Nepal. In the coming time, better work can be seen in agroforestry in Nepal. There is also an almost similar option of gurjan in Nepal.

Wood is available in sufficient quantity in Vietnam. Eucalyptus is sufficient there. The government itself manages the wood plantation there. Maximum work is being done on cold press. They calibrate the plywood mostly. Their production process is slightly different from India.

India is the biggest market for Nepal. The demand for wood in Nepal is low at the domestic level. Therefore, it has become necessary for Nepal to conform to QCO standards to sell goods in India.

MP Singh: When imported wood is tested in India, they sponsor the project of this sample. We make different products from it and test it. If we do not take the certificate of wood, then it will not be viable. Because it should be decided that what are the basic elements of wood? You can get that report from our institute.

Hem Prasad: Core veneer is also exported to India from Nepal. Because its strength is good. We have been manufacturing plywood for 15-20 years. The notion that Nepal’s plywood is of relatively low quality is not gemione. After getting the license of BIS, our plywood will be tested, only then the whole situation will become clear. If we find any deficiency, then we will definitely make the necessary arrangement to upgrade. Along with Uttis wood, we have Chinoli wood as an alternative to Gurjan. It is also used in making door frames. Uttis grows naturally in our place. It is true that it is necessary to check its authenticity.

MP Singh: You should definitely get your wood samples tested. Different types of wood should be tested. Japan also go for testing of wood and gets its report.

Manoj Gwari

Businessman from Nepal had applied to BIS in December itself. And BIS has also accepted their applications. Some industrialists have been sent letters in January asking them to deposit the fee for the visit to inspect their units. As Dr. Singh said, the delay in the process might be due to the overload of applications. It is also possible that the delay is due to the long period of elections.

Bureau of Indian Standards prepares standards only after taking feedback from the industries. A standard is decided after going throught the feed back of the industries and the minimum requirement of the product. The inspection team who visit the unit will assess according to the prescribed standards. This is a very simple and easy process. Regarding the application for BIS, the industrialist of India were assured to get the certificate within a month. This was claimed, but it has not happened, practically.

But for Nepal or any other foreign countries, this process is a little more time consuming. First, the unit will be visited, samples will be taken from them and a certificate will be issued on the testing result. Nepalese industrialists have applied for IS 303, 1960 standards.

New standards are in the process of being published. Standards 4990 and 710 have been published on the website. Changes are in the interest of the industry. It can be easily obtained. We still have eight months left. Due to elections, the pace of work is slow right now. Government machinery is likely to become normal from July 1. There may be hurdles in export of Nepal for the next three months after February 2025. The reason for this is that BIS has more than 250 products, for which QCO has to be implemented. BIS is short of staff. Whenever BIS goes to another country for inspection, at least three days are kept for one unit.

As far as Vietnam is concerned, no initiative has been taken till now. If a unit is inspected in July, the sample will come to India in August. It will take two to two and a half months to test a sample. After the sample is tested, the license process will also take the same amount of time.

Suresh Bahety

The plywood industry is going through challenges these days. Be it India or Nepal. It is important that the industrialists of both India and Nepal follow the standards of the BIS. And make their quality according to the standards. If the standards and quality are maintained at par, then a competitive platform will be available for both the countries equally. Your product is cheap, whatever the reason there may be. It may be due to the quality or it may be cheap due to cheap raw material. But due to this, plywood manufacturers of North India face problems with Nepal’s plywood. When the standards of quality will become equal, then such problems will be sorted out automatically.

Sita Ram: The faster the BIS certifies our products, the easier it will be to compare the goods of both countries.

Sita Ram: The faster the BIS certifies our products, the easier it will be to compare the goods of both countries.

Gajendra Rajput

Due to the difference in prices, the Indian plywood market keeps questioning the quality of plywood from Nepal and Vietnam. Their quality is fine in itself. Because in every industry, high and low quality goods are produced.

There can be some problem in the product in any factory at any of the time, it can be resolved. There is no need to worry. Standards can be met. Yes, dedication to comply is must.

Subhash Jolly: The time has arrived, we should discuss quality. Only quality products should reach the consumers. The initiative taken by India is definitely a big effort in this direction.

After the implementation of QCO, be it of India or imported one, standard of quality will be homogenous. It will be a win-win situation for both-consumer as well as Industrialist.

It is always our endeavor that the plywood industry touches new heights. BIS is speeding up the process of licensing. It is expected that in coming days, more and more producers will have BIS licenses.