Technology helps Industries stay competitive Globally

- February 6, 2025

- 0

- Why is technology advancement necessary in the industry?

Technology advancement is essential to improve productivity, reduce costs, and enhance the quality of products. It helps industries stay competitive in the global market and meet evolving customer demands. Additionally, advanced technologies often lead to sustainable practices, aligning with modern environmental requirements.

- What is the normal lifespan of a technology? When should the industry think about upgrading to the latest machines?

The normal lifespan of technology is typically 8–10 years, depending on the type of industry and machinery. Industries should consider upgrading when production starts facing inefficiencies, product quality declines, or when competitors adopt advanced solutions.

- How will the industry cover the depreciation cost of replacing machinery with upgraded technology?

To cover depreciation costs, industries should invest in durable and cost-effective machines. Advanced machines lowers production costs and minimize waste, leading to long-term savings. Proper financial planning and regular maintenance also help manage these costs effectively.

- Have you ever calculated your yearly expenditure on R&D (with respect to your turnover/profits)?

Yes, we allocate around 10–15% of our annual turnover to R&D. Our focus is on developing innovative, efficient, and cost-effective machinery that meets our customers’ needs while addressing industry challenges.

- What motivates you for R&D?

Our primary motivation for R&D is addressing the evolving needs of our customers and tackling new challenges in the plywood industry. We aim to develop technologies that not only solve current problems but also anticipate and fulfill future requirements.

Company Machines Overview

- L Type Panel Jointer Machine: Designed to help plywood manufacturers to utilize 3-foot core veneers to create full 8×4 feet panels, addressing a major challenge in the industry.

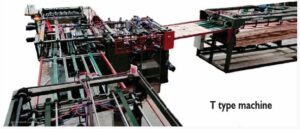

- T Type Machine: An economical solution for users who do not wish to invest in both core composers and L Type machines. This versatile machine performs both panel making and core composing tasks efficiently. Chopal Engineering Pvt. Ltd. – Innovating for the plywood industry.

👇 Please Note 👇

Thank you for reading our article!

If you don’t received industries updates, News & our daily articles

please Whatsapp your Wapp No. or V Card on 8278298592, your number will be added in our broadcasting list.

Ply insight launched on March 2018 with a vision to make a platform to collaborate plywood MDF, Laminate, machinery manufactures with dealers in the Trade.

Categories

Useful Links

Follow Us