Wood substitutes threaten plywood industry

- March 12, 2019

- 0

Wood substitutes threaten plywood industry

A CPWD proposal to ban use of timber in construction has

generated friction between manufacturers of wood

substitutes and plywood,

with each side claiming their product is superior.

A PROPOSAL by the Central Public Works Department (CPWD) to ban use of timber in construction from April 1993 is pitting the plywood and wood panel industry against wood substitute manufacturers. The former stand to lose CPWD orders worth Rs 70 crore and even more should state construction departments implement CPWD’s proposal.

A PROPOSAL by the Central Public Works Department (CPWD) to ban use of timber in construction from April 1993 is pitting the plywood and wood panel industry against wood substitute manufacturers. The former stand to lose CPWD orders worth Rs 70 crore and even more should state construction departments implement CPWD’s proposal.

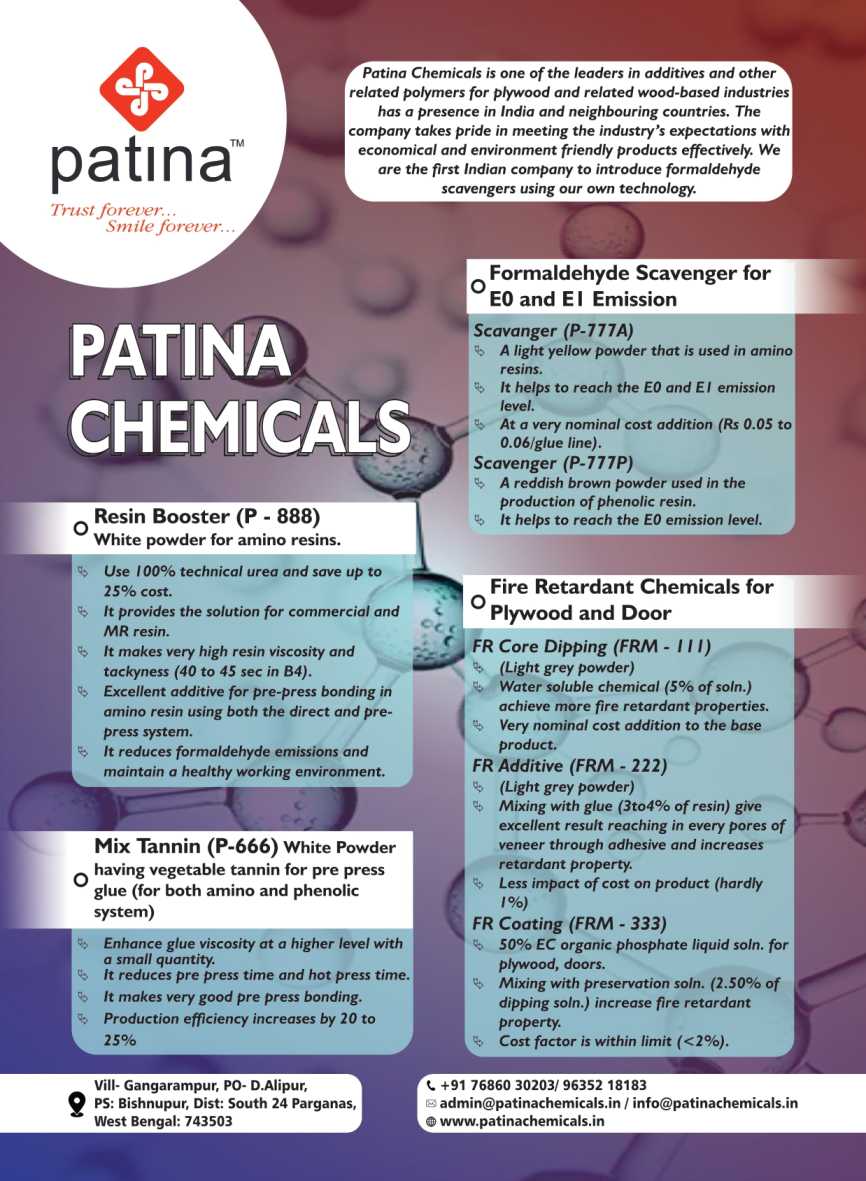

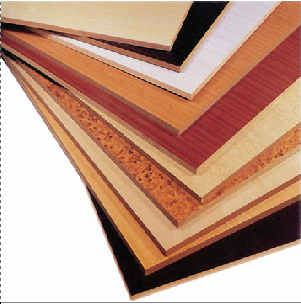

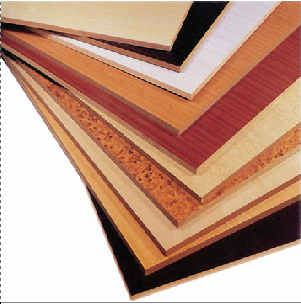

If the CPWD proposal is implemented, it will benefit the wood substitute industry. Wood substitutes are generally made from agro wastes such as bagasse, rice husk and cotton stalk or from wood that cannot be used as timber, such as twigs and small branches. Engineers, however, say any material that replaces wood is a wood substitute.

These materials are slowly gaining acceptance among the major furniture manufacturers. “These are finding application in the manufacture of tables, television cabinets and computer furniture,” says P K Sinha of Bhutan Boards Products Ltd, which manufactures particle boards, a wood substitute. Sinha’s company is marketing ready-to-assemble furniture made from particle board.

However, the Federation of Indian Plywood and Panel Industry (FIPPI), representing 62 large units and about 500 small manufacturers, contends wood is irreplaceable.

Santosh Goenka, regional manager of Kitply Industries Ltd, a leading plywood manufacturer, dismisses wood substitutes and says, “There is no substitute for wood. None of the wood substitutes — steel, aluminium or plastic — can give the same stiffness as wood.” His stand is corroborated by some CPWD engineers who insist “wood is so versatile, no single material can replace it. Each application of wood has to be examined separately.”

Goenka also asserts that manufacturing wood substitutes is “extremely harmful to the environment”. And, FIPPI has submitted a note to CPWD pointing out, “Roughly 30 and 70 times more energy is required for producing one tonne of steel and aluminium, respectively, compared to the energy required to produce one tonne of wood.”

FIPPI cites a Forest Research Institute study that shows use of plywood can result in saving upto 60 per cent of timber. But wood substitute manufacturers dispute this, saying, a lot of wood is wasted while manufacturing plywood. “We already are short of forest cover and are importing timber.”

Meanwhile, the plywood and panel industry is planting trees to provide for its own timber requirements.

Kitply, says Goenka, is planting 5 lakh trees every year which will meet its timber needs. Over the last year, there has been a spate of advertisements inviting investments in plantation schemes run by several Madras- and Bangalore-based companies. But wood substitute manufacturers maintain these plantations will not help to stop deforestation and the import of wood. “The trees will be available only after at least six years. One can only speculate about the plantations being done by the smaller plywood manufacturers.”

Ashwini Sarda, regional manager of Mangalam Timber Products Ltd, which manufactures a wood substitute called medium density fibre board, says, “Awareness about the environment is increasingly influencing the purchases of the government.”

But some plywood manufacturers have advertised their product also as environment-friendly. Clearly, an advertisement war appears to be looming on the horizon.

Courtesy: downtoearth