Vaidyanathan Hariharan

- अक्टूबर 4, 2021

- 0

E0 Plywood & Boards – Standards & Practices (Part 3)

E0 manufacturing parameters

E0/CARB P2/JIS F****/Super E0 – all these are some of the popular formaldehyde emission standards used for composite wood products. E0 boards do not mean only the resin/glue has to be E0 or zero free-formaldehyde. The whole process of making E0 boards must be carried out with discipline, cleanliness and professionalism.

E0 plywood/boards is a mindset; E0 boards is not a product – Vaidya

Based on recommendations, the factory premises where E0 boards are manufactured must have formaldehyde content in the air ≤0.1 PPM.

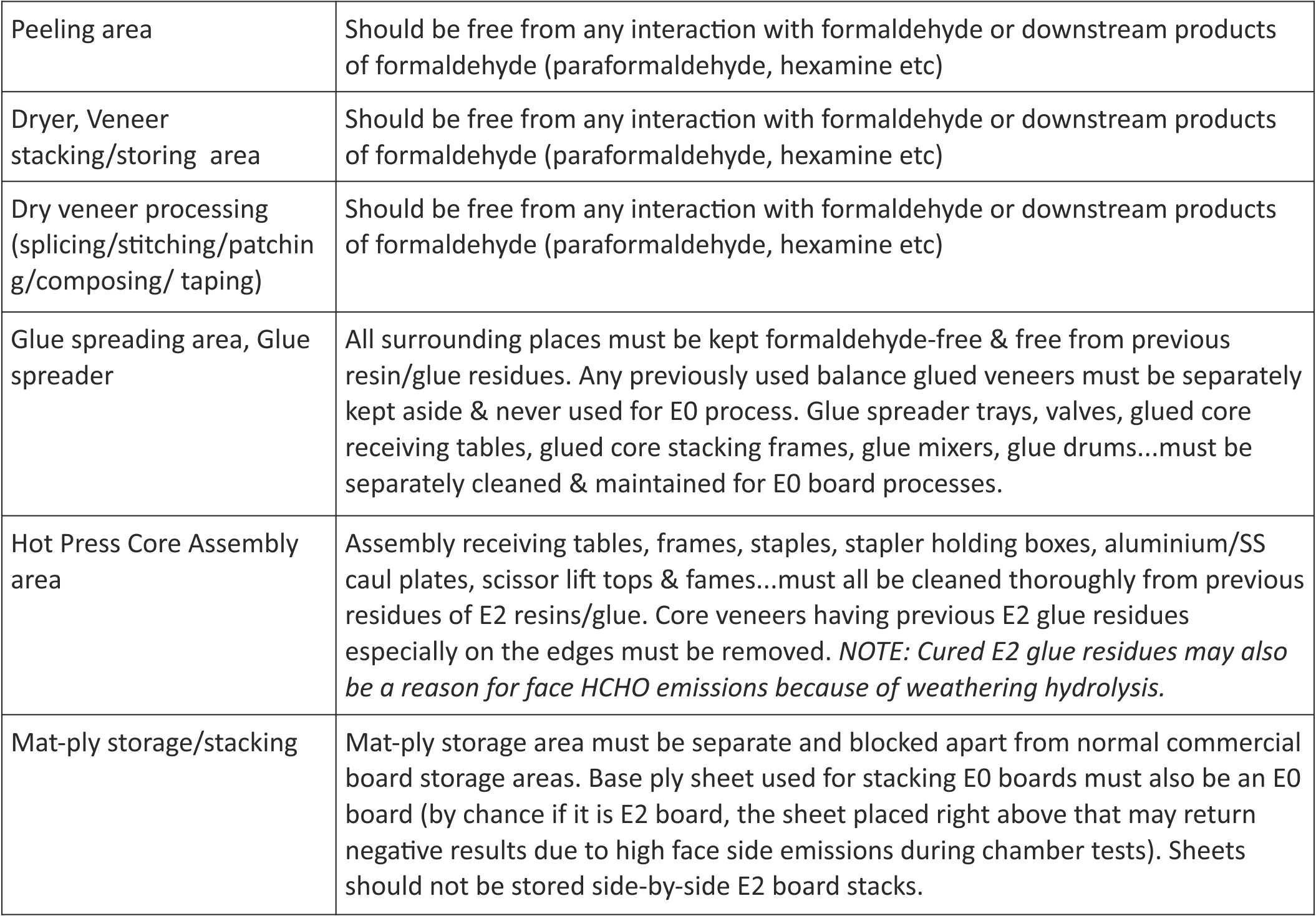

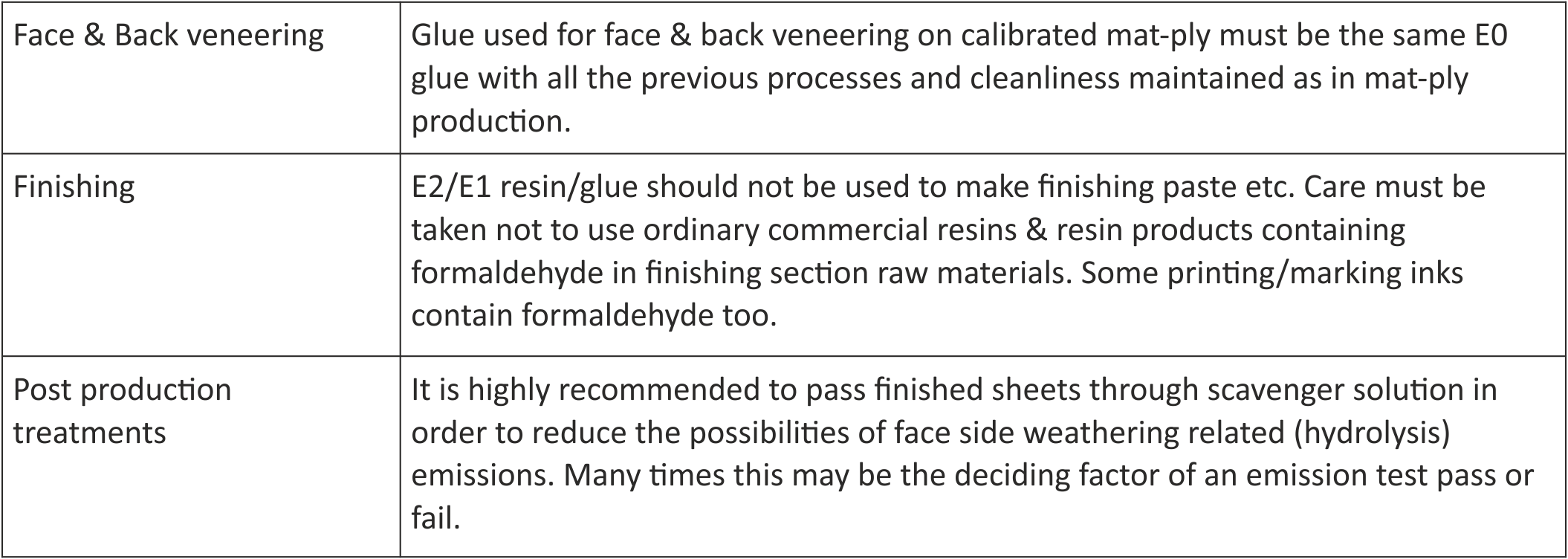

E0/CARB P2 board manufacturing parameters:

Cleaning of equipment & surfaces for E0 process: All equipment such as glue storage tanks, valves, pipelines, glue mixers & lids, glue drums & valves, glue spreader rollers & trays, receiving tables & stacking frames, caul plates & all surfaces used for handling core veneers, face veneers…must be soak-cleaned thoroughly with a water solution made using 5% urea & 5% liquor ammonia mixture. Glue mixers are a major cause of concern in small factories.

Every year, we clean factories & equipment during Ayudh Pooja / Deepavali / Viswakarma Pooja.

For E0 Board manufacturing, every day must be a similar Pooja.

KRDF works on product development, process development, standardisation and skill development in manufacturing sectors ranging Sustainability, Biodegradable Single-use Materials, Alternate Natural Material Composites, Coir-Bamboo-Agrowaste Composites, Budget Housing, and Rural technologies.

https://www.linkedin.com/in/krdf

krdfindia@outlook.com